Physical & Mathematical Modeling

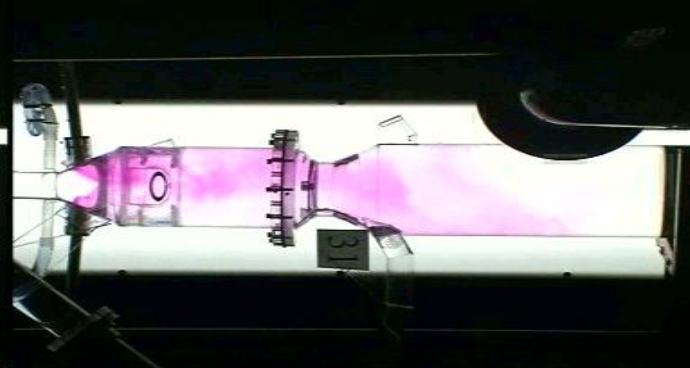

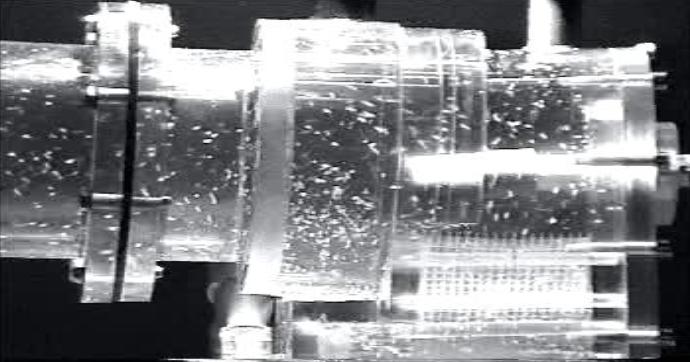

Modeling gives an insight into the flames interaction with the secondary air stream so the flame can be visualized inside the process.

MEEMCO Mine & Metals uses a number of different techniques to build up a picture of what’s happening inside the process. Physical and mathematical modelling can help solve many combustion related problems and there are often many benefits that flow from correcting these issues.

Features

-

Temperature profiles and heat flux inside the process are presented graphically

-

Graphic representation of the flames interaction with the secondary air stream

-

Concentrations of species can be followed inside the process, ie O2, CO, CO2, NOx, CaCO3 etc

-

Report with images generated and includes technical drawings of the suggested modifications for direct implementation of the solution

-

Improvement actions can be planned and installed during a scheduled shutdown, minimizing downtime and risk

Benefits:

-

Solve difficult combustion related problems of buildup, refractory or fuel consumption

-

Reduced fuel consumption

-

Longer refractory life

-

Increased production and improved product quality

-

Problem solve off-line without risk to plant or product quality

-

Determine optimal burner position and operating parameters